The "Green Oriented" Philosophy

Our product sustainability strategy focuses on evaluating and improving all aspects of a product's life cycle, from eco- design to end-of-life. For the production of our products, we favor materials with low environmental impact, such as recycled or natural ones, and we do not use any hazardous substances.

Products that adhere to this philosophy contain at least 80% low-impact materials, excluding metal parts and accessories. But we don't stop there... every product classified as GREEN ORIENTED passes a series of tests to ensure it can withstand the stresses and wear typical of real-world use, thus ensuring compliance with our high quality standards.

Our "Green Oriented" philosophy isn't just a corporate approach, but a promise of continuous improvement and an unwavering commitment to a greener and more sustainable world. With every purchase, our customers actively participate in reducing their environmental impact, helping us protect the planet for future generations.

USING RECYCLED MATERIALS: THE ADVANTAGES

To counteract these negative effects, Carpisa has chosen to use recycled materials, thus reducing the use of non-renewable resources, avoiding the need to extract new non-renewable raw materials like oil, and reducing the amount of waste that could harm ecosystems. This approach allows us to improve resource efficiency and support a circular economy, where materials are reused rather than discarded, repurposing resources that would otherwise be wasted.

THE ADOPTION OF NATURAL MATERIALS

Among the natural materials we use are organic cotton, certified according to the Global Organic Textile Standards (GOTS) or the Organic Content Standard (OCS), and regenerative cotton, certified Regenerative Organic Cotton (ROC). We also use materials such as straw, bamboo, and cork, all renewable and biodegradable, which further reduce the environmental impact of our products.

Our dedication to our work, respect for the environment, and commitment to future generations are the foundation of our "Green Oriented" philosophy. We continually seek and implement new methods to reduce our environmental impact, aiming to create a sustainable future. Each "Green Oriented" product represents our commitment to combining quality, innovation, and respect for nature, inviting our customers to join us on this important journey towards sustainability.

Our "Green Oriented" philosophy isn't just a corporate approach, but a promise of continuous improvement and an unwavering commitment to a greener and more sustainable world. With every purchase, our customers actively participate in reducing their environmental impact, helping us protect the planet for future generations.

WHAT ARE THE LOW IMPACT MATERIALS WE USE?

At Carpisa, we're constantly committed to finding new solutions to reduce and minimize the environmental impact of our products. Here's an overview of the materials most commonly used in our eco-sustainable production lines:

- 50% Recycled Rubber

- CARPISA GOTECH®

- R-PET

- RPP

- Organic Cotton

- Bamboo

Under study:

- Hemp

- Cork

- RPU

CERTIFICATIONS AND SUSTAINABILITY STANDARDS

The recycled materials used come from both pre-consumer recycling processes, which reintroduce production waste into the production cycle, and post-consumer recycling processes, with materials certified according to international standards such as the Recycled Claim Standard (RCS) and the Global Recycled Standard (GRS).

For our tags and packaging, and wherever possible, we favor FSC (Forest Stewardship Council) certified materials, which attest to sustainable forest management and biodiversity conservation. This way, we minimize our environmental impact while ensuring the quality that distinguishes the brand.

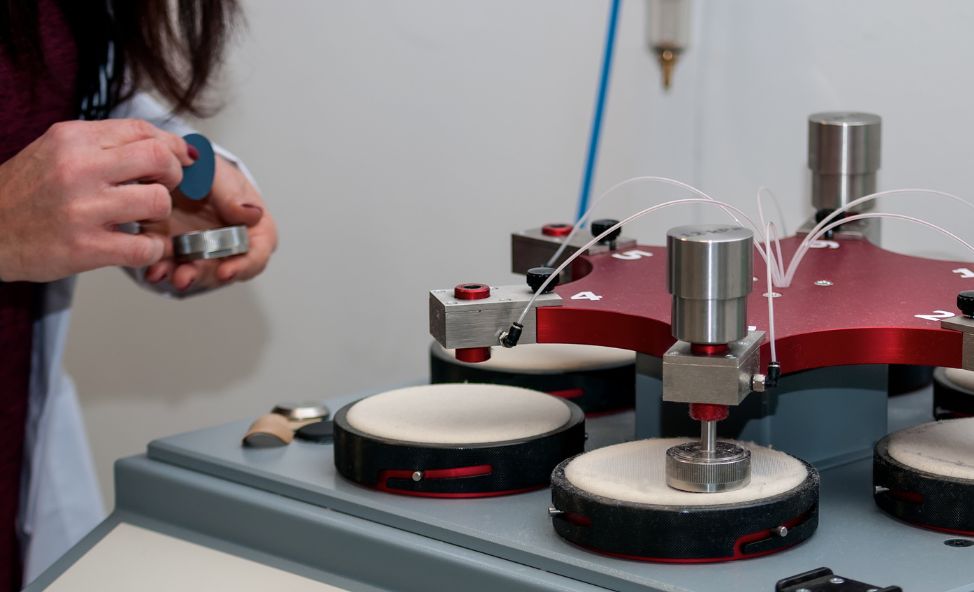

QUALITY CONTROL AND PRODUCT SAFETY ACTIVITIES

Our laboratories conduct the main fabric tests to identify the materials' composition and their physical and mechanical resistance. The main tests include:

- The identification of the material;

- Resistance to traction, tearing and abrasion;

- Resistance to color bleeding, water penetration and surface wetting;

- The measurement of the main physical characteristics, such as thickness, yarn definition, weight and color change.

Furthermore, our laboratories can perform physical-mechanical tests on finished products to identify their actual performance, pushing the products to the extreme of their use:

At our CARPISA Lab, all materials undergo specific testing to verify their compliance with current product quality and safety standards. Using cutting-edge instruments, such as the ELMENDORF (tear resistance), the Martindale (abrasion), the dynamometer for elongation at break, the spray test for waterproof materials, and the FTIR (infrared spectroscopy), we evaluate and verify that 95% of samples meet the design/prototype specifications during the design phase. If any discrepancies are detected once production has begun, production is immediately halted and the product is reworked according to the appropriate parameters.